Gravimetric Extruder Control - GravEx

Control your Extruder

Control Product Quality

Save over 2% Raw Material

Quick Job Changes

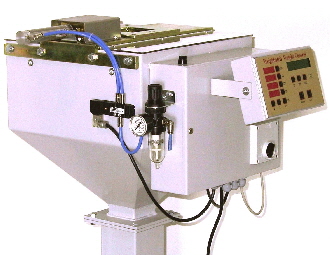

The GravEx is a gravimetric extrusion control system which utilises the loss in weight principle to control and maintain a consistent weight or thickness of your extruded product. It will maintain your product weigh to better than +/- 0.5% of target.

It will automatically react to variations in material bulk density, extruder back pressure, ambient conditions and any other influence to extruder output stability to maintain your product consistency.

How it Works

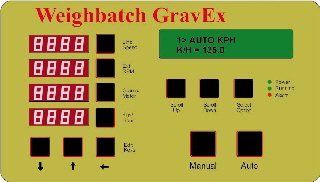

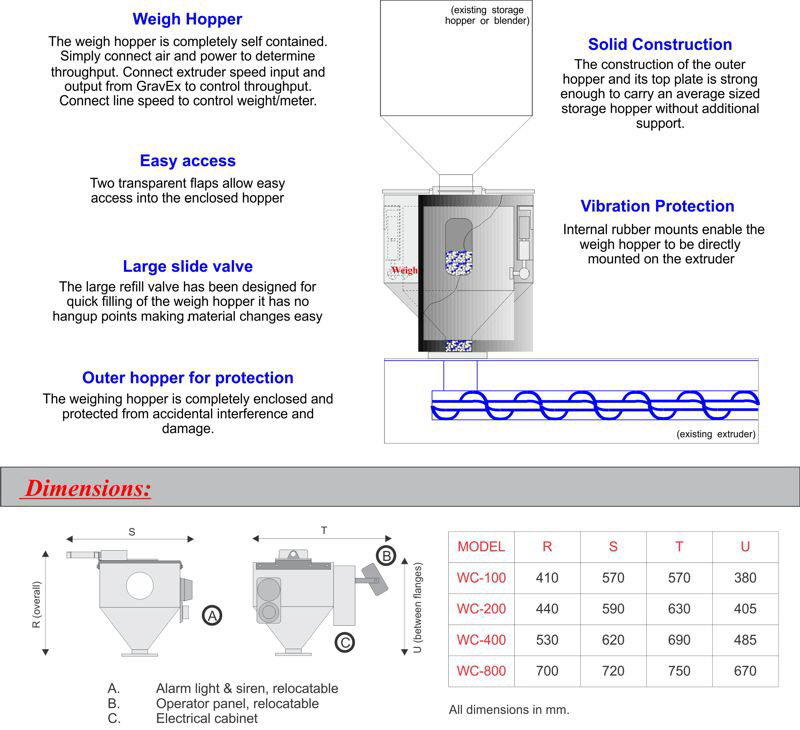

The GravEx throughput controller sits between the material storage hopper and the extruder throat. It monitors the loss in weight of the material in its weigh chamber and from this calculates the mass throughput rate of the extruder. In Auto Control mode GravEx can control the extruder or the process line speed to maintain a set output or a set product weight per unit length.

When the weight of material in the weigh chamber falls below a preset value a slide valve opens and refills the chamber from the material storage hopper.

To prevent damage to the load cells the GravEx has a protective outer hopper made from powder coated zinc plated steel. The inner weigh chamber and the inlet slide valve are made from 304 grade stainless steel. The control electronics are mounted in a cabinet attached to the outer hopper.

Interface Modules

In order to operate the GravEx controller needs input from the process: The extruder screw speed and the process line speed. In order to control it needs to be able to change the extruder screw or process line speed. There are many ways this can be done depending on the control wiring for the main system.

Rather than run potentially hazardous signals from the main electrical cabinet to the GravEx controller, a set of interface modules are installed in the main electrical cabinet and a low voltage communications cable run to the Gravex controller.

All control signals are optically isolated. Speed input modules can use digital pulses or analogue voltage input. Extruder and line control can be by motorised potentiometer, digital output, relay output or analogue output.

Control Outputs

Fundamental to the design of GravEx is the philosophy that when not in Auto Control mode, the extruder or line speed control should revert to the normal operator control. To best achieve this GravEx uses control signals to increase or decrease the speed rather than setting an absolute speed using an analog reference output. The preferred control outputs are motorised potentiometer (for older lines) or direct ramp up/down digital inputs to the line PLC (for newer lines). Analog control output is the least desirable option because it almost impossible to avoid a step change of speed when changing from Auto to Manual control mode.

Features:

- The GraveEx will control your extruded product to +/- 0.5% of target by adjusting either the extruder screw speed or the line speed thus maintaining your product quality and eliminate over weight/usage.

- Automatically compensates for process variations caused by raw material bulk density variation, extrusion back pressure, ambient conditions and any other factors affecting extruder output stability.

- Very quick responce time which can shorten job change and set up time by more than 30% resulting in increased production time and reduced waste.

- The weigh hopper is completelt enclosed by a metallic hopper to isolate it from external interference and provides mechanical protection of the load cells giving you a long and reliable service life.

- Integrated adaptor flange for feed throat mounting , top flange designed to mount machine hooper or blender.

- Stand alone, co-ex or fully integrated with Weighbatch AdvanTec central control system.

- Standard models for 100, 200, 400 & 800 kg/hr.

- Throughput or weight per metre control standard.

- Dynamic parts in contact with the material are stainless steel.

- Static parts in contact with the material are powder coater steel.

- Power supply single phase 230 V, 50 Hz std.

- Pneumatic air supply 6 bar, regulator supplied

- Output control modules for 10 turn potentiometer, push botton or PLC speed control.

- Thickness display for film applications, requires entry of width and density.

- Wall thickness disply for pipe applications, requires entry of diameter and density.

- Remote mounted operator controls.

- High temperature version for hot dried material.

Specifications: Options:

Weighbatch Ltd, 167 Ellis St, PO Box 5421 Frankton, Hamilton, New Zealand, Ph + 64 (0)7 847 0230, Fax + 64 (0)7 847 2919, info@weighbatch.com

Copyright © 2011 Weighbatch (NZ) Ltd